Custom Finishes: A Comparison of Electroplating, PVD, and Powder Coating

In the world of door hardware, creativity is no longer constrained by the shape of a lever. Thanks to the multitude of custom finishing methods now available, you can achieve a dazzling array of colours, from California coral pinks to shimmering golds and everything in between. Today, we’ll explore some of the most popular methods for colouring door hardware and the unique effects they can produce. So, whether you’re a seasoned designer or looking to do a small renovation, read on to discover the many possibilities for bringing your door hardware to life with colour.

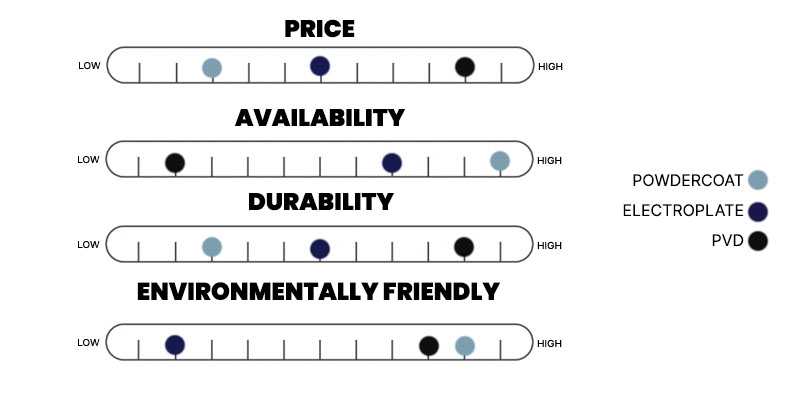

In Australia, there are three primary types of custom finishing used for door hardware – electroplating, physical vapour deposition (PVD) and powder coating. The finish that can be used depends on the type of metal that the hardware is made from. Below, we will compare the pros and cons of these three finishing methods and explore the metals they are best suited for.

Electroplating

Electroplating is a process of depositing a thin layer of metal onto a conductive surface. The process involves placing the object to be plated, known as the substrate, into a solution containing ions of the metal to be deposited. An electrical current is then passed through the solution, causing the metal ions to bond to the substrate and form a thin, durable coating. The thickness and quality of the coating can be controlled by adjusting the electrical current and the composition of the plating solution.

In other words, the product is dipped into a solution of salt and metal pieces, which is then charged electronically, causing the small metal pieces to stick to the original product.

This is done to improve the base metal’s appearance and durability. It is most commonly found in products made of brass, copper, iron, nickel, titanium, or zinc.

Electroplating is commonly used for door hardware finishes such as brass, chrome, and nickel, but custom finishes in bronze, black, and many shades in between can also be applied.

PROS |

CONS |

|

|

|

|

|

|

|

|

|

|

|

Physical Vapor Deposition (PVD)

Physical Vapor Deposition (PVD) is a vacuum process used to deposit a thin layer of metal onto a surface, creating a durable and wear-resistant finish. It is a popular choice for door hardware and tapware due to its long-lasting properties. Unlike electroplating, PVD does not require a clear or top coat to maintain its durability. This process is commonly used on materials such as titanium, zirconium, aluminium, stainless steel, and copper.

PROS |

CONS |

|

|

|

|

|

|

|

|

|

|

|

Powder Coating

Powder coating is a dry powder application process that creates a hard and even metal finish. The process involves electrostatically applying the powder to the surface of a metal object and curing it under heat. Powder coating coats the metal instead of binding to it like electroplating and PVD, making it more susceptible to everyday wear and tear. However, powder coating has a low carbon footprint and can be recycled and reused, making it an environmentally friendly option. It is available in a variety of colours and textures, making it a popular choice for door hardware made of galvanized steel, stainless steel, mild steel, zinc alloy, and aluminium. Additionally, powder coating is a more cost-effective method of finishing over the other two and is usually available in smaller quantities.

PROS |

CONS |

|

|

|

|

|

|

|

|

To sum up, each of these metal finishes has its unique advantages and drawbacks. The ideal finish for your door hardware will depend on various factors, including your timeline, budget, location of use (interior vs. exterior), quantities required and the other finishes used throughout your project that you want to match. So, carefully consider your needs and preferences before making a final decision. By choosing the right finish, you can give your door hardware a beautiful and functional upgrade that will last for years to come.

For more information on what finish would suit your needs best or to help make a selection, reach out to our estimators today.